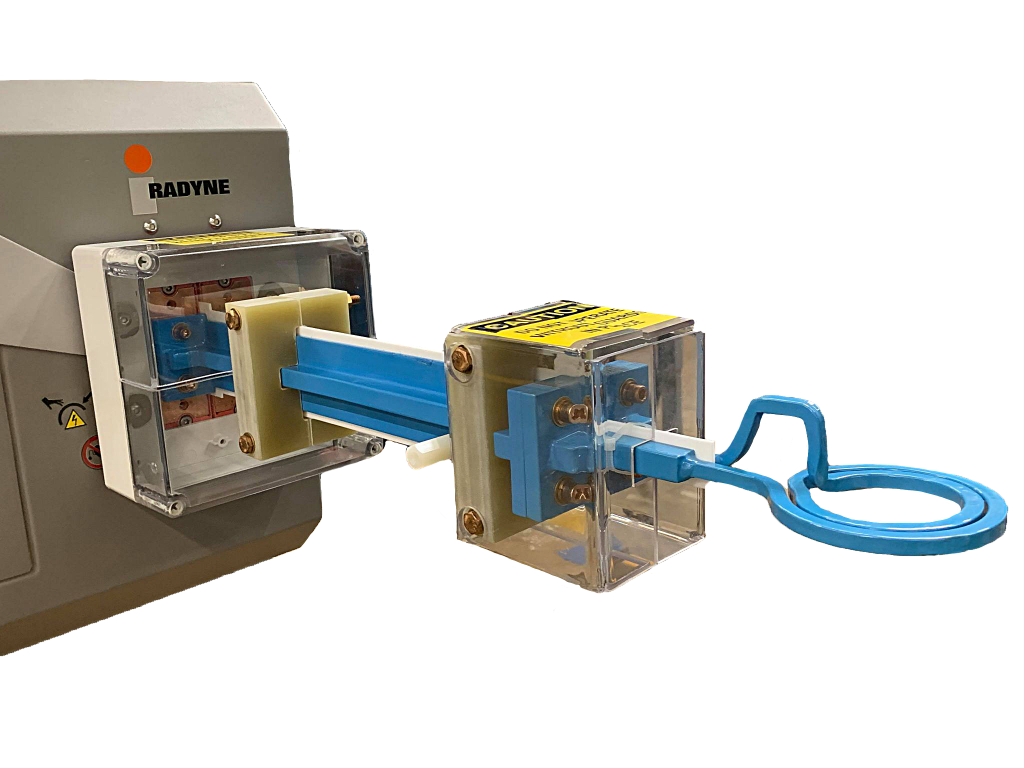

Inductor Design and Development

Successful induction heating largely depends on the design and quality of the inductor and quench head that will give the desired profile.

Radyne’s experience in research and development of inductors across a vast spectrum of applications provides the essential improvements that deliver superior heating of parts. As one of the many proficiencies of the Induction Process Engineering Center (IPEC), our dynamic team also focuses on delivering innovative quality inductors and quenches with increased durability and efficiency for superior heating profiles. Equally important, each inductor is built specifically to meet the needs of our customers.

The IPEC team also provides full support and service for the repair, rebuild, and maintenance of inductors regardless of the coil manufacturer.

Inductor Services:

- Inductor & Susceptor Modeling, Design and Manufacture

- Quench Design Combinations

- Machined Integral Quench Inductors

- Inductor Encapsulating

- Refractory Cast and Ceramic Inductor Liners

- Inductor Quick Disconnects

- Inductor Repair and Maintenance

- Emergency Pick-Up and Drop-Off Service

- Water-Cooled Buswork

Click here to learn about aftermarket inductor repairs and maintenance