Coil Repairs

At Radyne, we leverage state-of-the-art Finite Element Analysis (FEA) modeling to meticulously design our induction coils, ensuring the highest efficiency in heating properties. Our FEA modeling process allows us to simulate and analyze the thermal and electromagnetic performance of our coils, optimizing their design for maximum effectiveness and energy efficiency. This advanced technology enables us to predict and mitigate potential issues, resulting in superior product quality and performance.

Our full-service coils department is equipped with the latest tools and technologies, enabling us to manufacture precision induction coils that meet the stringent requirements of our clients. Our capabilities include custom coil design, prototyping, testing, and production, ensuring that each coil is tailored to the specific needs of the application. We have a team of experienced engineers and technicians who work closely with our clients to understand their requirements and deliver solutions that exceed their expectations.

In addition to our advanced modeling and manufacturing capabilities, we also offer comprehensive support services, including installation, maintenance, and repair. This ensures that our clients receive not only top-quality products but also the ongoing support needed to maintain optimal performance.

By combining cutting-edge technology, expert knowledge, and a commitment to excellence, Radyne is able to provide industry-leading induction heating solutions that deliver unmatched efficiency, precision, and reliability.

Inductor Express Service:

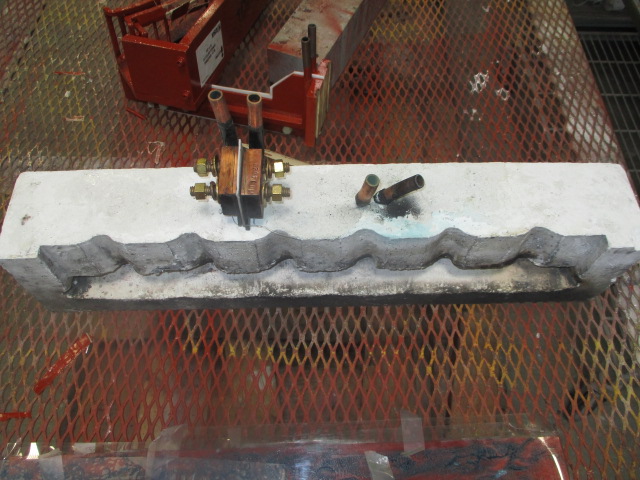

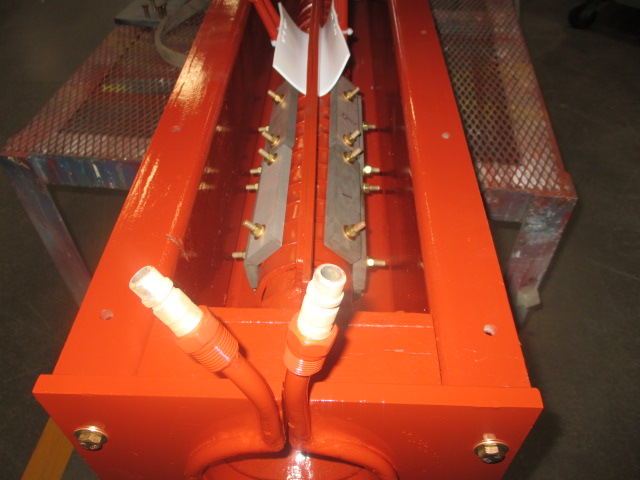

- Coil repairs & maintenance

- Inductor-quench combinations

- Emergency pick up and drop off service

- Replacement inductors for various styles

- Inductor coatings & poured mold inductors

- Quality control prior to release “ship”

- Customer coil stocking for rapid delivery

Contact us about coil repairs, refurbishment, or to purchase spare coils..

| Before and After |  |  |

| Before and After |  |  |

| Before and After |  |  |

| Before and After |  |  |