Safety

Induction Heating Safety

Many studies have been conducted to evaluate the direct and indirect effects of electromagnetic field (EMF) exposure on health, passive and active medical implants, and hypersensitivity. Several national and international organizations including the Institute of Electrical and Electronic Engineers (IEEE), International Radio Protection Association (IRPA), World Health Organization (WHO), Occupational Safety & Health Administration (OSHA), and others have developed awareness programs regarding non-ionizing radiation and evaluation of the health risks associated with external field exposure when using any electromagnetic device (such as cell phones, household electrical appliances, computer monitors, transmitting antennas, microwave ovens, induction coils, and others). A large body of scientific research exists and a number of international standards, guidelines, and regulations have been put into effect. For example, in the U.S. these include the following standards:

- IEEE: C95.6 Safety levels with respect to human exposure to electromagnetic fields, 0 to 3 kHz.

- IEEE: C95.1 Safety levels with respect to human exposure to electromagnetic fields, 3 kHz to 300 GHz.

All manufacturers of electromagnetic devices (including induction heating manufacturers) must comply with international/national standards and regulations related to controlling external exposure to EMF in the workplace.

There is no universal guideline for so-called “safe stand-off distances” for employees with medical devices or people without them, because such distances are application-specific and greatly depend on coil design details, applied power and frequency, presence of other electromagnetic devices in coil surroundings, and other factors. The magnitude of an external magnetic field can be either computer modeled or measured. For example, at Radyne Corporation we use both techniques.

In some cases, the induction coil is not the main source of EMF exposure and other electromagnetic sources (e.g., transformers, bus bar networking, electromagnetic lifting devices) might contribute to an even greater degree to the magnitude of EMF.

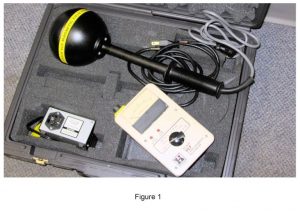

A number of devices are available to measure EMF exposure in the workplace, ranging in applied frequencies and designs. Based on our experience, three-axis measuring devices provide acceptable accuracy if properly used and calibrated. For example, for a number of years Radyne Corporation has been using the following equipment: Holaday 3-axis VLF Magnetic Field Meter HI-3637 (Fig. 1). This device is capable of providing isotropic measurements of a magnetic field’s magnitude. The instrument is designed to conform to the requirements issued in the IEEE protocols and guidelines for suitable frequencies.

Following are some general guidelines for monitoring and supervision of EMF exposure:

- Running conditions of the induction system: The machine should be running with the maximum running parameters for output KW or the maximum allowable running current/voltage to the coil.

- Measurement specifics: The induction machine envelope should be drawn and measurements should be taken at the operator station (or where other people may be present) and at a number of points around the perimeter of the machine at distances from the machine of 0.25, 0.5, 1, 1.5 meters, etc. (whatever is most appropriate) and different heights from the floor. Data should be reviewed and a report issued to indicate whether the measured values comply with safety requirements. All readings should be taken and properly documented including setup parameters for capacitor and output transformer settings. If necessary, measurements should be made to calculate the coil running current for the specified meter readings.

Over the years, manufacturers of induction machinery have developed a number of ways to minimize external magnetic field exposure in cases where it exceeds maximum permissible levels. This includes a number of patented designs and proprietary techniques including passive and active magnetic shields, magnetic shunts, and Faraday rings, to name a few.

Dr. Valery Rudnev, FASM

Director, Science & Technology