ScanMaster™ High-Performance Induction Scanners

ScanMaster™ Induction Scanners

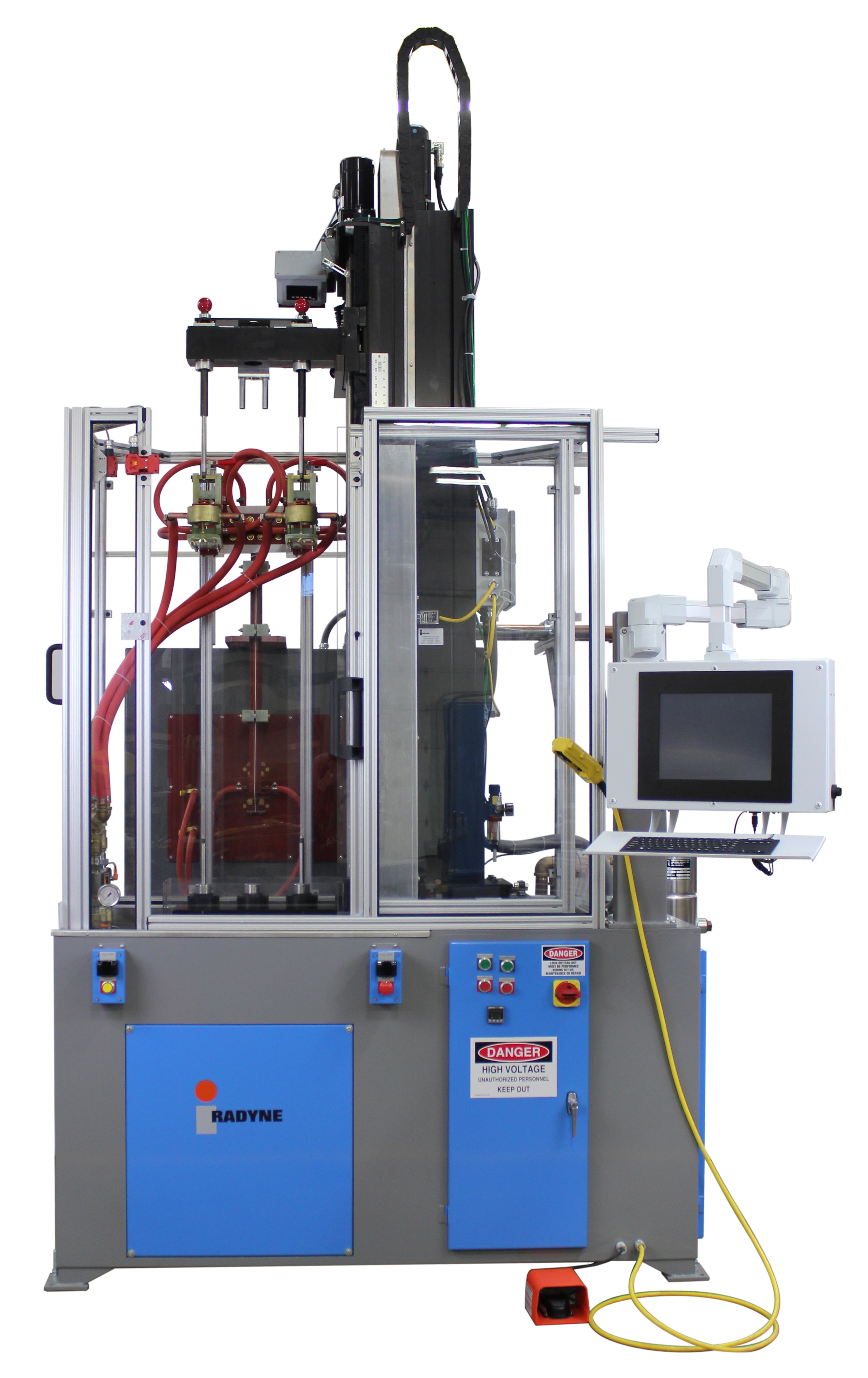

Introducing Radyne’s Cutting-Edge ScanMaster™ Induction Scanners

Unlock the potential of advanced heat-treating processes with Radyne’s flagship induction scanner lineup – ScanMaster™. Designed to cater to a diverse spectrum of needs, our ScanMaster™ induction scanners offer unparalleled versatility in handling a wide range of part weights, lengths, and shapes. From components weighing mere ounces to hefty 5000-pound loads, and parts shorter than an inch to an impressive 120 inches in length, Radyne’s ScanMaster™ systems set the standard for high-performance induction scanning.

Key Features of ScanMaster™ Induction Scanners:

-

Versatile Design:

Our ScanMaster™ induction scanners are meticulously engineered to accommodate a variety of heat-treating processes, making them a perfect fit for your unique requirements.

-

Modular Flexibility:

With modular design at the core, these systems offer the flexibility to modify or interchange components as your production demands evolve.

-

Comprehensive Package:

A typical ScanMaster™ induction scanner includes essential components such as the scanner base, scanning tower, power supply, induction coil, standard guarding, safety light curtains, ScanMaster™ (Motus) controls package, and configurable water & quench cooling systems.

-

Diverse Range:

Radyne proudly presents four versions of the ScanMaster™ System. From the compact ScanMaster™ 28, capable of accommodating parts up to 28 inches long and 75 pounds in weight, to the robust ScanMaster™ 120, boasting an impressive 120-inch scan length and a remarkable weight capacity of 5000 lbs.

Why Choose Radyne ScanMaster™?

Manufacturers worldwide place their trust in Radyne’s ScanMaster™ induction scanners. Our reputation for precision, reliability, and cutting-edge technology makes us the preferred choice for industries seeking top-notch heat-treating solutions. Browse through our ScanMaster™ systems below and elevate your heat-treating processes with Radyne’s innovative technology.

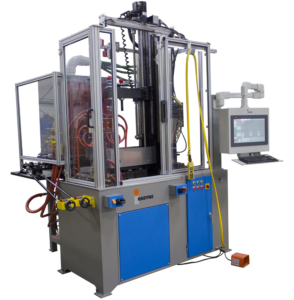

ScanMaster™ 28: Precision Heat-Treating for Compact Components

Discover the ScanMaster™ 28, a compact yet powerful induction scanner designed to elevate your heat-treating processes. With a generous 28-inch scan length and a capacity to hold up to 75 pounds, this versatile model brings precision and efficiency to lightweight components. Unleash the potential of advanced heat treatment with the trusted reliability of Radyne’s ScanMaster™ 28.

Scan Length: 28 inches [71 cm]

Max Payload: 75 lbs [34 kg]

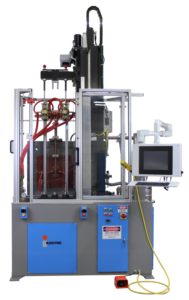

ScanMaster™ 44: Unmatched Performance for Medium-Sized Parts

Introducing the ScanMaster™ 44, a game-changer in heat-treating technology. This dynamic model boasts a 44-inch scan length and a remarkable capacity to hold up to 500 pounds. Ideal for medium-sized parts, the ScanMaster™ 44 redefines precision and control in heat treatment. Experience industry-leading innovation with Radyne’s ScanMaster™ 44.

Scan Length: 44 inches [111 cm]

Max Payload: 500 lbs [226 kg]

ScanMaster™ 63: Precision Heat-Treating, Extended Reach

Elevate your heat-treating capabilities with the ScanMaster™ 63, designed for exceptional performance. With an extended 63-inch scan length and a robust capacity of 500 pounds, this model offers precision and versatility for a wide range of applications. Trust in Radyne’s expertise to deliver unmatched results with the ScanMaster™ 63.

Scan Length: 63 inches [160 cm]

Max Payload: 500 lbs [226 kg]

ScanMaster™ 120: Unrivaled Power for Heavy-Duty Heat Treatment

Experience the pinnacle of induction scanning with the ScanMaster™ 120 – a heavyweight in the world of heat-treating. Boasting an impressive 120-inch scan length and an unmatched capacity of 5,000 pounds, this model is engineered to handle the most demanding tasks. Radyne’s ScanMaster™ 120 sets the standard for precision, reliability, and performance in heavy-duty heat treatment processes.

Scan Length: 120 inches [304 cm]

Max Payload: 5,000 lbs [2,268 kg]

Choose Radyne’s ScanMaster™ lineup to revolutionize your heat-treating operations. From compact components to heavy-duty tasks, our models offer unrivaled precision, modularity, and cutting-edge technology for superior results. Explore the range today and witness the differences trusted by manufacturers worldwide.

Elevate Your Heat-Treating Processes with Radyne ScanMaster™

Experience the future of heat-treating with Radyne’s ScanMaster™ induction scanners. From precision engineering to modular versatility, our systems are tailored to meet the demands of various industries. With a diverse range of versions designed to handle a wide array of part weights and lengths, Radyne’s ScanMaster™ is the ultimate solution for achieving exceptional heat-treating results. Explore our ScanMaster™ systems today and discover the difference trusted by manufacturers globally.

Features

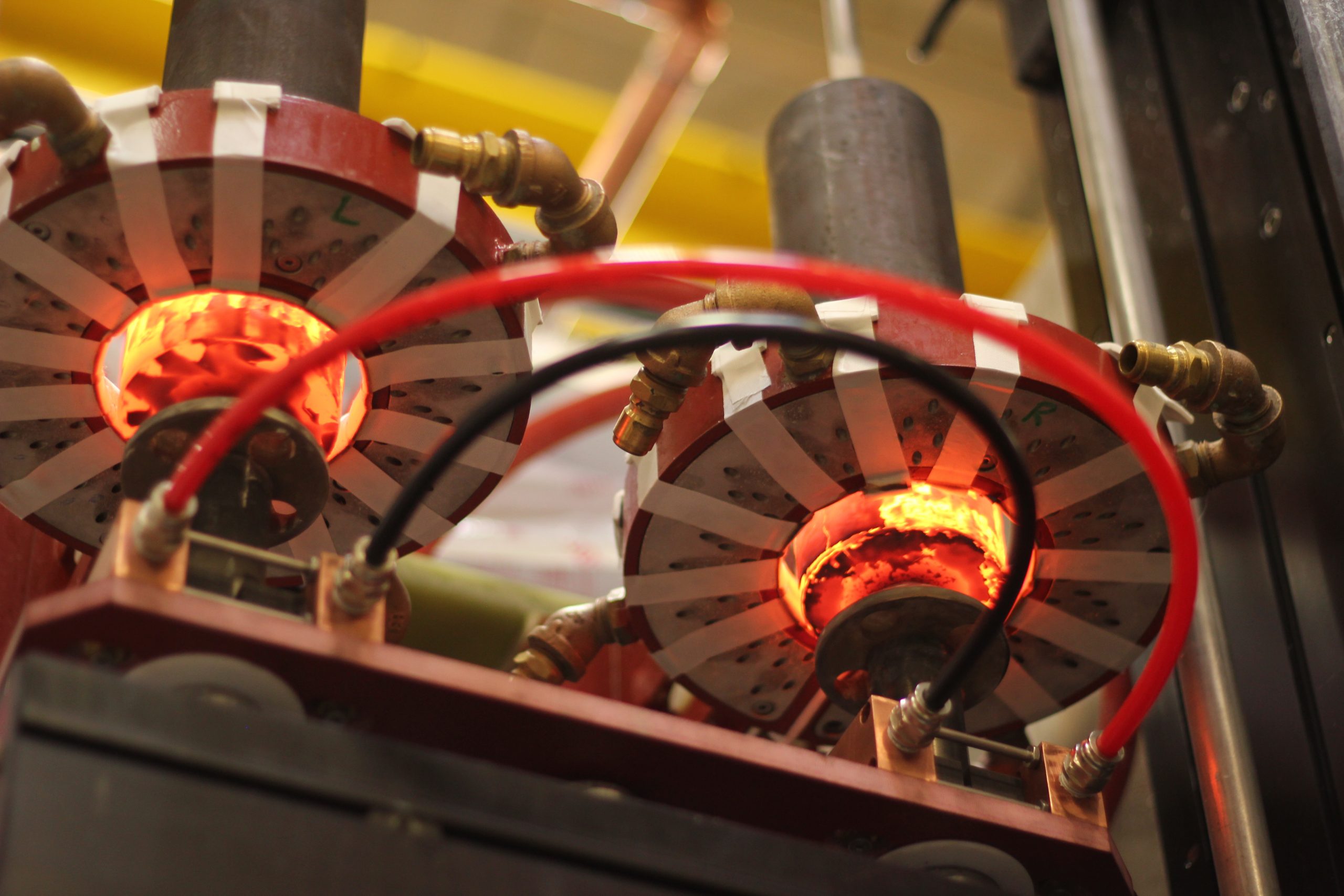

- Single, Dual, or Triple Spindles: Achieve enhanced efficiency with systems featuring single, dual, or triple spindles for running one, two, or three up operations.

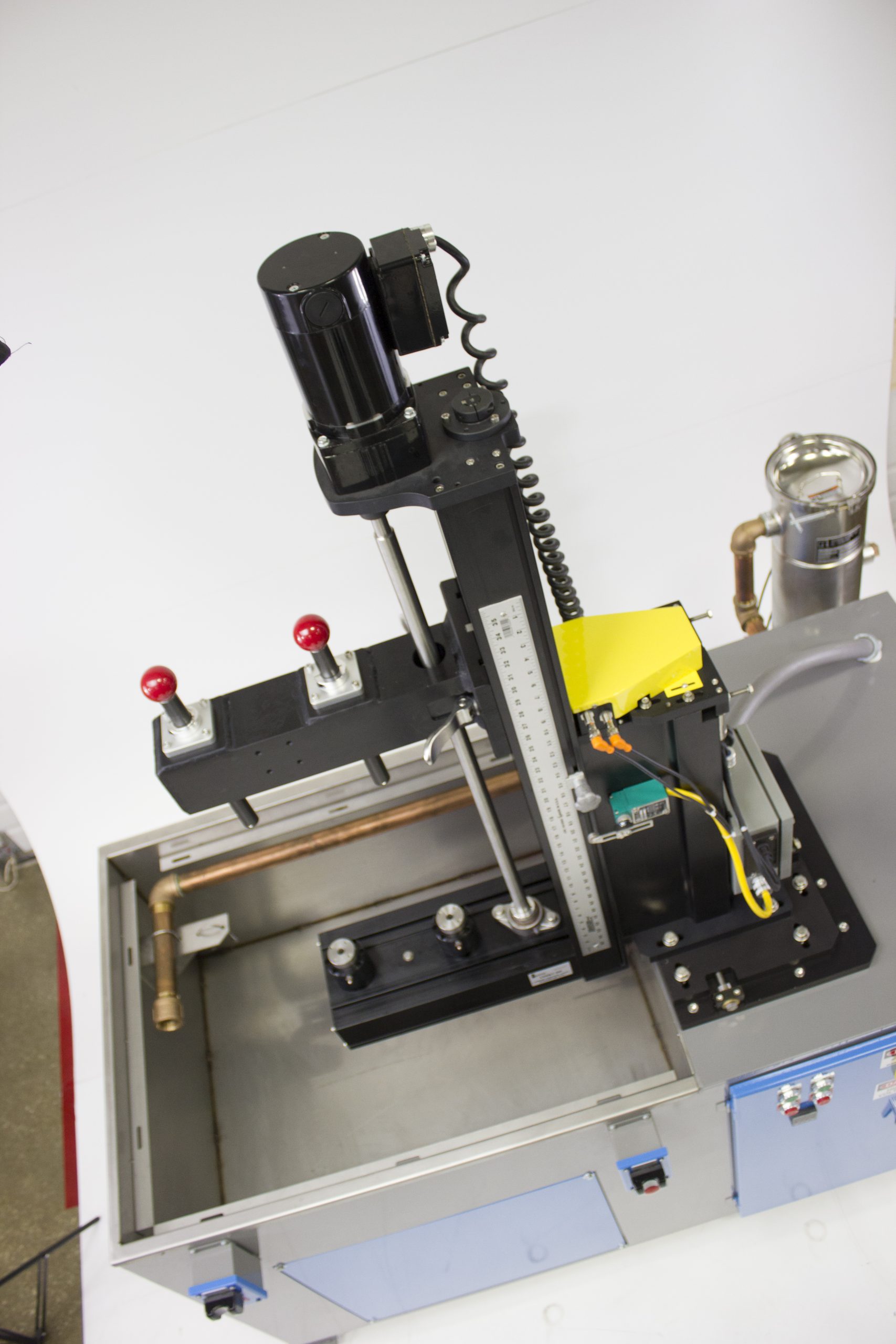

- Stainless Steel Quench Basin: Our systems feature a built-in stainless steel sink basin designed to resist corrosion.

- Customizable Guarding: Our unique transparent guarding allows for virtually limitless customizability. The guarding of your machine is specifically designed to suit your needs, whether you are hand loading or using any range of material handling systems. It also allows for easy 360-degree viewing of the machine for easy diagnostics.

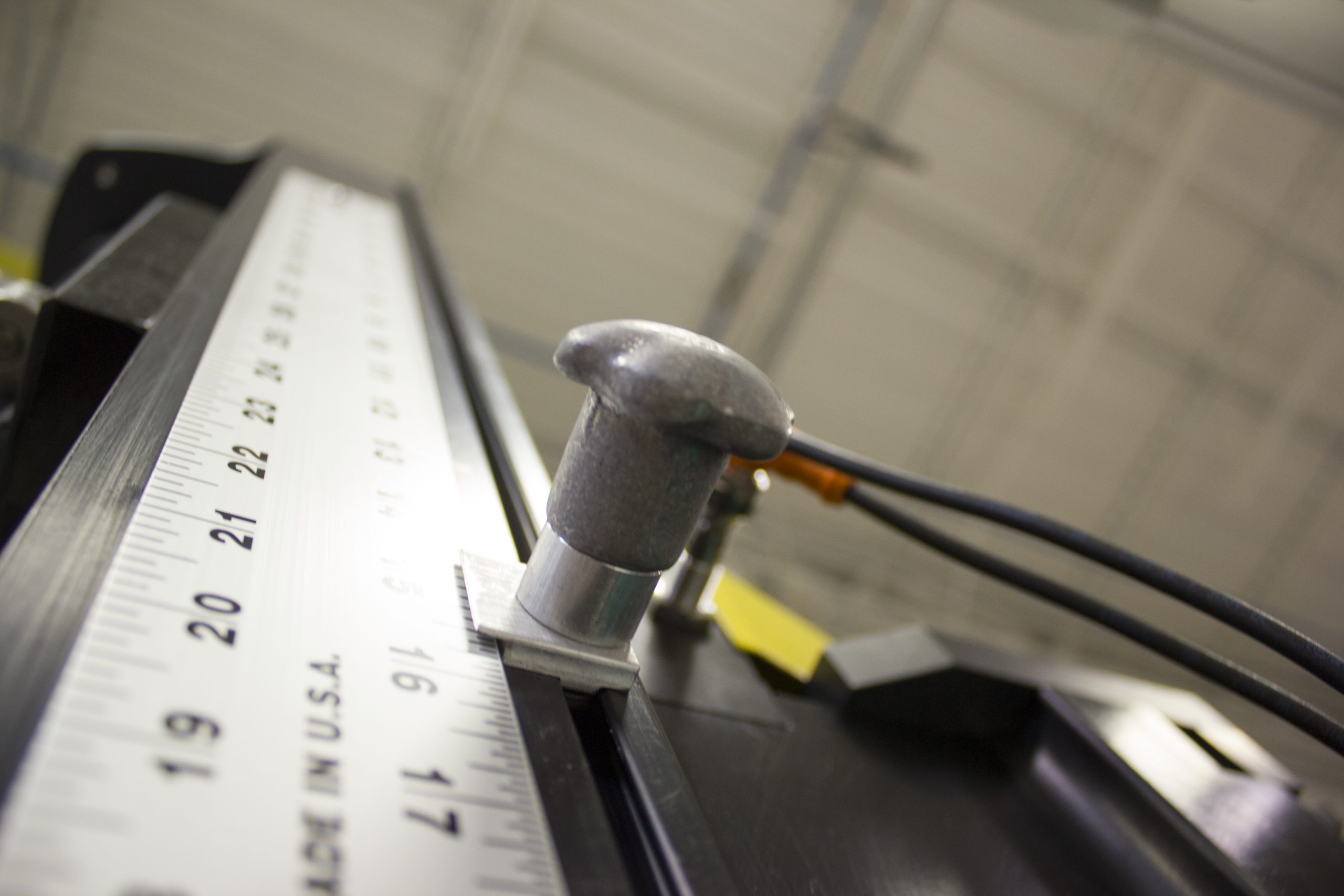

- Motorized Upper Center: Changeovers made easy. Our systems feature a motorized upper center spindle, allowing for quick and convenient adjustments. Experience efficient production transitions and reduced downtime with Radyne’s advanced technology.

- Self-contained System for Work Cell Integration: Seamlessly integrate our self-contained induction systems into your work cell. Benefit from hassle-free setup and precision heat-treating that enhances your manufacturing processes.

- Application-Matched Precision Hardening: Tailor your operations with different power supply ratings and frequency ranges available for application-matched precision heating. Achieve optimal results with technology designed to meet your unique needs.

- User-Friendly Controls: Simplify your workflow with Radyne’s user-friendly MOTUS controls that streamline setup, changeover, and diagnostics. Radyne’s systems make precision heating accessible and efficient.

- Simple Utility Connection: Experience fast and cost-effective installation with our induction systems featuring simple utility connections. Get your operations up and running swiftly with Radyne’s easy integration and installation services.

Tech Specs

| ScanMaster® 28 | ScanMaster® 44 | ScanMaster® 63 | ScanMaster® 120 | |

| Scan Length | 28 in. [71 cm] | 44 in. [111 cm] | 63 in. [160 cm] | 120 in. [304 cm] |

| Spindles | Single or Dual Spindles | Single, Dual, or Triple Spindles | Single, Dual, or Triple Spindle | Single Spindle (3-Jaw Chuck)z |

| Spindle Spacing | 8 in. [203 mm] | 6 in. [152 mm] | 6 in. [152 mm] | — |

| Rotation Speed | 0-400 RPM | 0-175 RPM | 0-175 RPM | 0-60 RPM |

| Max Payload | 75 lbs | 500 lbs | 500 lbs | 5000 lbs |

| Max Single Part Diameter | 18 in. [457 mm] | 20 in. [508 mm] | 20 in. [508 mm] | 30 in. [762 mm] |

| Max Dual Part Diameter | 6 in. [152 mm] | 8 in. [203 mm] | 8 in. [203 mm] | — |

| Dimensions | 77W x 38D x 91H in. [195W x 97D x 231H cm](121H in. [307 cm] Fully Raised) |

77W x 38D x 116H in. [195W x 97D x 294H cm] (150H in. [391 cm] Fully Raised) |

82W x 76D x 143H in. [208W x 193D x 363H cm] (170H in. [431 cm] Fully Raised) |

186W x 104D x 180H in. [472W x 264D x 457H cm] (210H in. [533 cm] Fully Raised) |

| Operator Interface | MOTUS Touchscreen Controls | MOTUS Touchscreen Controls | MOTUS Touchscreen Controls | MOTUS Touchscreen Controls |

| Quench Tank | 200 gal./50 GPM [757 L/189 LPM] 300 gal./100 GPM [1135 L/378 LPM] |

200 gal./50 GPM [757 L/189 LPM] 300 gal./100 GPM [1135 L/378 LPM] |

200 gal./50 GPM [757 L/189 LPM] 300 gal./100 GPM [1135 L/378 LPM] |

1600 gal./400 GPM [6056 L/1514 LPM] |

Optional Technology

- Quick Disconnect Coil Mounting: Elevate efficiency with quick change tooling and coil mounting. Experience rapid change-overs with Radyne’s Quick Disconnect technology.

- Robotics and Material Handling Integration: Revolutionize your operations by integrating robotics and material handling with your ScanMaster™ system. Our technology seamlessly accommodates integrated bowl feeders, rotary tables, step feeders, conveyors, and 6-axis robotic arms, enhancing your workflow.

- X-Box Controller Operation: Our MOTUS control software allows scanner controls to be mapped to an X-box style controller to aid in ease of use and setup.

- QAS Monitoring and Alerting System: Elevate your process monitoring and traceability with the QAS Monitoring and Alerting System. Gain insights into each part processed, enhancing your quality control and production efficiency.

- Automatic Quench Monitoring: automatically monitor quench concentrations and

- Remote Quench Pod or Quench Media Exchanger: Enhance the control and flexibility of your ScanMaster™ system with a remote quench pod or quench media exchanger. Streamline your quench change-over process while Improving floor space utilization.

- VersaTemp Pyrometer Control Integration: Achieve advanced temperature control with VersaTemp Pyrometer control integration. Ensure accuracy and consistency in your heat-treating operations by allowing one or more pyrometers to interface directly with your system’s power supply.

- Pneumatic Door: Experience convenience and safety with a pneumatically actuated door. Streamline access and workflow while prioritizing operator safety and well-being.

- Footswitch: Optimize hands-free operation with a footswitch. Take control of your heat-treating processes with enhanced convenience and flexibility.

- X/Y Adjustable Table for Heat Station: Tailor your heat station and coil alignment with an X/Y adjustable table. Achieve precise positioning for optimal heating results.

- Motorized X/Y Table: Make adjustments to your X/Y table with the press of a button. Integrated with our MOTUS controls and compatible with the controller.