Tempering

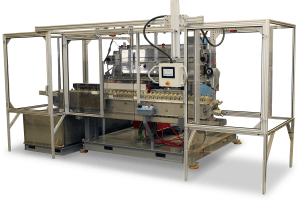

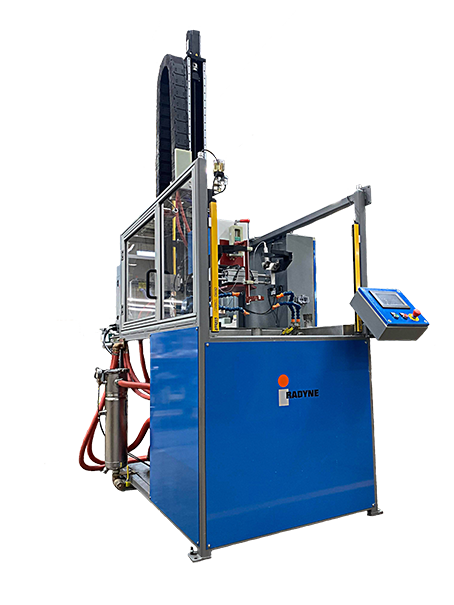

Extensive production experience in recent years has demonstrated the commercial success of tempering quench hardened steel by induction heating. The general interrelation of tempering time and temperature in production to decrease the given hardness of quench hardened steel has been known for a long time. Metallurgically, the application of induction heating for tempering has been related to the use of higher temperatures and shorter tempering times. Economically, induction heating for tempering has proven particularly adaptable to automation in production lines.

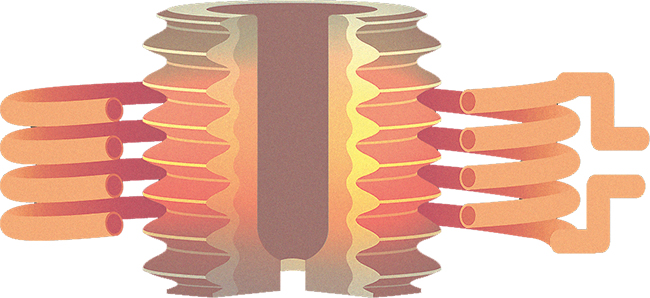

Induction tempering is particularly applicable to hardened bar stock. In this instance the bars are progressively passed through a coil or inductor to provide the proper tempering cycle as a determined from the desired hardness. Tempering and shrink fitting operations may be combined.

Selective Tempering

Design of parts may require selective softening as well as hardening. Highly restricted heat patterns, made possible with induction heating, can be particularly helpful in such cases and may also provide important economies in the overall processing sequence.

Progressive Tempering

Progressive induction hardening may precede induction tempering in such cases.