Effective Ways of Joining Using Induction Heating Technology

Abstract

Induction heating is a very controlled and cost-effective way of heating parts for bonding or joining applications. This presentation will talk about what induction is and why manufacturers are switching to induction over other heating processes for their joining and bonding needs. Applications covered include brazing and soldering, weld pre-heating, seam welding, shrink fitting, hard surfacing alloy bonding, adhesive and paint curing, heat staking, and heat sealing. Advantages to manufacturers include flexibility to process a variety of parts with relatively rapid changeover, efficient use of energy, time, and shop floor space, and economical processing of both large continuous production runs or small batch jobs.

Introduction

Induction heating is different from other processes used for heat treating and joining parts in the way that the heat is delivered. Traditional industrial heating processes (e.g., furnaces, torches, salt baths) heat the surface of the part by use of a thermal fluid (e.g., hot gas or molten salt) around the part or by thermal radiation (i.e. vacuum furnaces). Heating rates are therefore limited by the thermal-energy transfer rate at the surface of the part.

Induction heating uses an AC (alternating current) electromagnetic field to generate energy within the part. This causes heating at the surface and subsurface areas of the part due to Joule effect (I2R power losses: where I is current density induced in the part by the electromagnetic induction field and R is the electrical resistance of the part). The second possible cause of induction heating is hysteresis heating, but it can only appear when heating ferromagnetic bodies.

Since induction heating is an electromagnetic process, the amount of energy put into a part can be controlled very precisely, assuming the part is consistently and accurately positioned relative to the inductor. (Accurately positioning the part relative to the inductor is important because the strength of the electromagnetic field can be dramatically deformed due to several electromagnetic phenomena including end effects, edge effects, proximity effects, and many others.) When an induction generator is turned on, energy transfer to the part begins. When the generator is turned off the energy transfer ends. In other words, induction can be viewed as a controlled energy input process.

In some instances, induction is used to heat parts that are not electrically conductive through the use of a susceptor (a material that absorbs electromagnetic energy and converts it

into thermal energy, which is then transferred to the electrically non-conductive part through conduction).

Process Parameters of Induction Heating

The differences between how induction and thermal heating processes heat parts necessitate that the processes be controlled in different ways. Processes that use thermal fluids for heating are controlled by varying the heating fluid temperature and heating time. Radiant heating processes are controlled by varying the temperature of the radiant heating elements (furnace temperature) and heating time.

Induction heating equipment transfers energy into the heated part by means of a changing electromagnetic field. It is varying of the electromagnetic field intensity, frequency and time that control part heating rate and temperature. The electromagnetic field intensity is controlled by the inductor (also commonly called a coil) geometry, the power and voltage applied to the inductor, and where the part is positioned relative to the inductor. Note that part temperature is an output of the induction process, not an input like with most traditional industrial heating processes where the processing fluid temperature becomes the part temperature.

Other process parameters that have an impact on how parts inductively heat are part geometry and material properties of the part. Variation in part geometry can change the mass of the part and the final part temperature. Also, if the changes in the part geometry change where the eddy currents run in the part, the energy distribution with the part can be changed as well as peak surface temperatures.

Generally, the material properties that influence induction heating are chemistry, grain structure, electrical conductivity, thermal conductivity, and magnetic properties.

Advantages of Induction Heating

It is because of the more precise control and more repeatable results over traditional heating methods that manufacturers are going to induction heating. When they make the switch, the following are the benefits that are realized:

- Increased energy efficiency: Induction heating is often far more efficient than other traditional methods.

- Increased precision: Very precise control is maintained over how much energy and where it put into the part.

- Increased process control: Very repeatable heating can be achieved on parts because of the precise energy input control that induction heating provides.

- Increased speed: Part can be heated to joining temperatures in a few seconds to several minutes compared to hours in an oven or furnace.

- Conversion from batch to lean manufacturing: Induction heating lends itself to JIT (just in time) and single-piece flow processing. Because of its speed and the fact that there is no furnace or refractory heat up and cool downtime associated with induction heat treating, single parts can be processed as needed.

- Safety: No open flames and the fire hazard associated with the use of torches or gas-fired ovens and furnaces.

Induction Joining Applications

Induction heating is commonly used to join metal components together. Typical induction joining processes include, but are not limited to brazing, soldering, shrink fitting, adhesive bonding/curing, heat staking, heat sealing, fusing nickel- boron hard-face coatings, and welding.

Discussion

Brazing and Soldering

Brazing and soldering are the two most popular induction joining applications. (Ref. 1)With both brazing and soldering, a filler metal is used that has a melting point lower than the solidus point of the metal parts being joined. After reaching a certain temperature, generally about 50° to 100°F higher than the melting temperature of the filler depending on heating rate, the surface of the base metal reacts with the filler alloy to form a metallurgical bond. According to the American Welding Society (AWS) the only thing that differentiates soldering from brazing is temperature. If the metal bonding process uses a filler metal that melts below 450°C (842°F) the bonding process is defined as soldering. However, if the filler metal melts above 450°C (842°F) then the bonding process is defined as brazing (Ref. 2).

Induction heating can be used to solder or braze with all of the various soldering and brazing alloys that are used when using oven, furnace, and torch soldering or brazing. These soldering alloys include, but are not limited to lead alloys, tin alloys, and zinc alloys. Lead and tin alloys are commonly used for soldering copper and brass joints. Zinc alloys are used for aluminum to aluminum soldering, aluminum to copper soldering, and repair of galvanized coatings. The brazing alloys that have been used with induction heating are aluminum braze alloys, silver braze alloys, gold alloys, platinum alloys, nickel brazing alloys, and copper braze alloys. Aluminum braze alloys are commonly used for brazing aluminum to aluminum joints, aluminum to copper joints, and aluminum to stainless steel joints. Silver braze alloys are commonly used with induction heating to braze carbide to steel joints, steel to steel joints, copper to steel joints, copper to brass joints, copper to copper joints, stainless steel to stainless steel joints and many other metal combinations traditionally brazed with silver alloys.

Brazing and soldering requires the entire joint to come up to bonding temperature for a quality bond joint to form. Because of this, generally lower power and lower frequency induction power supplies are used for these applications.

Induction heating is particularly well suited for allowing the combining of brazing with heat treating of the base part. Case in point, by selecting a silver braze alloy with a solidus point slightly higher than the austenitizing temperature (Ac3) of the base steel part, a carbide bit can be brazed in place, the braze alloy allowed to solidify and then the brazed assembly is quenched to develop a hardened base part. Following the quenching, the brazed assembly can be tempered to the desired final hardness using either induction tempering or oven tempering. When induction tempering is used, the brazing, hardening, and tempering of a part can occur in the timespan of several minutes instead of the hours in a furnace.

Induction heating is well suited for silver brazing large parts such as motor rotors in the timespan of minutes, which cannot be accomplished with torches or another traditional thermal heating process.

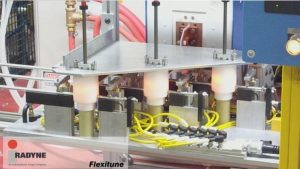

Induction heating when used in combination with protective atmosphere chambers allows for fluxless brazing of part assemblies with either copper or nickel alloys. Examples of assemblies that are brazed using induction heating and protective atmosphere chambers are automotive gas lines. Figure 2 shows an induction brazing machine with protective atmosphere chambers that is capable of copper brazing three fuel lines at a time. Figure 3 shows the fluxless copper brazed joint that is bonded on the machine in Figure 2.

Figure 4 shows more complex fluxless copper brazed joints that have been produced using induction and protective atmosphere chambers, demonstrating that parts do not have to be round in order to be brazed with induction heating. Click here to learn more about brazing and application practices.

Shrink Fitting

Shrink fitting is where two parts have a slight interference fit at room temperature where they cannot be pushed together by mechanical means for assembly. To assemble, one part is induction heated to an elevated temperature and the mating part may either be left at room temperature or cooled below room temperature, so that the changes in part geometry due to thermal expansion allows for the assembly of the two parts. Once parts are assembled and allowed to return to room temperature, the parts are locked together by a mechanical interference fit. Depending on the geometry and material of the components being assembled, shrink fitting temperatures usually range from 120° C (250° F) to 400° C (752° F). This type of application generally requires the entire part to be heated so low power and low frequencies are typically used.

Advantages of shrink fitting using induction are, it is quick, controlled and reversible. Examples of typical types of part assemblies where induction heating and shrink fitting are used are: hubs on shafts assemblies, bearing on shafts assemblies, motor stators assemblies, and motor rotor assemblies. Click here to learn more about shrink fitting and application practices.

Adhesive Bonding/Curing

With adhesive bonding/curing, the metal substrate to be coated is heated using induction heating to temperatures generally ranging from 200° to 400° F to cause an accelerated chemical reaction to occur allowing for the bonding/curing of the organic or polymer coating.

An example of adhesive bonding/curing are line pipe heating systems where induction is used for pre-heating prior to coating (fusion bonded epoxy (FBE) coating) and induction drying of API grade line pipe (Figure 7).

Induction is also used to accelerate the curing of paints on metallic parts. Paints that have cured and bonded with induction heating are: Solvent-based, water-based, powder, and epoxy paints. Figure 8 shows an example of an application where induction heating was used for paint curing.

Heat Staking

Heat staking is a process where a metal part is heated using induction heating and then inserted into a thermoplastic (plastic to metal bonding) allowing the thermoplastic to flow around the metal part filling in small holes or knurling to form a mechanical joint. Figure 9 is an example of a part produced using heat staking and induction heating. Heat staking using induction heating has the advantage over other heating processes in that metal parts can be heated in several seconds allowing parts to be processed as needed allowing for lean manufacturing. Click here for more information.

Heat Sealing

Induction heating has been used for two types of heat sealing, metal-to-glass sealing and metal-to-polymer (plastic) sealing. The most common type of heat sealing is metal-to-polymer and the focus will be on this type of heat sealing from here on.

Heat sealing is in its simplest form is a process where an aluminum foil is pressed up against a thermoplastic and then the aluminum foil is heated with induction to a temperature where adhesive bonding occurs between the aluminum foil, thermoplastic, and the lip of the container to be sealed.

Heat seals used on screw top containers are typically made up of a multilayer laminate that consist of a layer of pulpboard, a layer of wax, aluminum foil, and a layer of polymer that is compatible with the container material and capable of heat sealing to the lip of the container. The screw-on cap holds the multilayer laminate up tight against the lip of the container, and then an induction coil is passed over the top of the cap heating the aluminum foil in the multilayer laminate, causing the polymer to warm by conduction and adhere to the aluminum foil and lip of the container.

Heat sealing is used in a number of industries to create tamper proof packaging and create a seal that keeps out moisture and other contaminants. Some examples of industries that use heat sealing are listed in Table 1.

|

Industry |

Product Applications |

|

Agriculture |

Fertilizer |

|

Agro Chemical |

Pesticide |

|

Automotive |

Corrosion inhibitors, Motor oil, Anti-freeze, Additives |

|

Chemical |

Acids, Bleach, Paints, Household cleaning products |

|

Cosmetic |

Bubble bath, Hair preparations, Tattoo ink , Creams |

|

Dairy |

Milk |

|

Dental |

Toothpaste |

|

Flammable |

Lighter fluid, Acetone, Nail Polish Remover, Alcohol |

|

Food |

Edible oil, Peanut butter, Spices, Juices, Syrups, Sports bottles, Condiments |

|

Medical |

Vitamins |

|

Petroleum |

Motor oil, Additives |

|

Pharmaceutical |

Drugs, Solids, Liquid, Capsules |

|

Water |

Bottled water |

Table 1: Examples of industries and applications where heat sealing is used.

Fusing of Nickel Boron Hard coatings

Nickel Boron hard coatings are applied to steel parts by a two-step process. The first step in the process is to apply the coating by combustion powder Thermospray™, atmospheric plasma spray, or HVOF. The second step in the application

process is to fuse the coating to develop a fully dense microstructure free of porosity and oxides, and is metallurgically bonded to the metal substrate. The fusing of these hard coatings can be accomplished by using an acetylene torch, furnace, or induction heating. Of these three fusing methods, induction heating is capable of being automated, lends itself to lean manufacturing, and is capable of yielding the highest production rate. Normally, slow cooling of the fused parts is recommended because of differences in thermal expansion coefficients of the coating and substrate.

Welding

Induction heating is commonly used in three different areas related to welding, pre-heat prior to welding, seam welding, and post-weld heat-treating i.e. stress relieving and annealing of the weld(aka, seam annealing).

Many manufacturers are finding that induction heating is a very fast, controlled, cost-effective way of pre-heating medium carbon and alloy steel assemblies prior to fusion welding, i.e. hub and shaft assemblies.

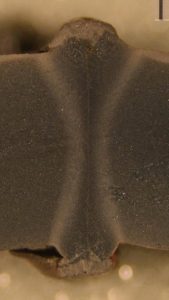

Seam welding can be accomplished with contact electrodes or using induction. Both employ high frequency current to heat up strip edges to a forging temperature. (Note: the strip edges are not actually brought to a melting temperature.) High-frequency induction seam welding is most commonly used for tube and pipe production where a strip is formed into a round, or other custom shapes, the formed strip passes through an induction coil, the strip edges heat up and are then compressed together to form a solid-state weld. There are two key advantages of this solid-state process compared to fusion welding methods. First, even if the strip edges reach a melting temperature, all high-temperature material is squeezed out of the bond line along with any oxides and contaminants, leaving a continuous metallurgical bond. Second, because the metal does not melt, it is possible to avoid cast structures, oxides, porosity, high-temperature precipitates or other detrimental metallurgical phases in the weld zone and heat-affected zone. The result is a stronger weld with a more uniform microstructure and improved mechanical properties compared to fusion welds. In addition, this process is capable of producing high-quality leak-free seam welds at high speeds (up to 600 feet per minute for heat exchanger tubing), thick walls (up to 24mm wall thickness for large diameter line pipe), and with a wide range of ferrous and non-ferrous alloy compositions. Figure 10 shows the cross-section of an induction welded tube seam. Note that any molten material (dendritic structure) that was present has been expelled for the weld interface and is present only in the weld flash at the upper and lower surfaces of the tube.

Induction tube seam welding is capable of welding clad metal that cannot be welded with fusion welding. Clad metals like copper-clad steel and 3XXX series aluminum clad with 4104 aluminum are examples of clad metals that cannot be welded by fusion welding because of the mixing of the cladding with the base metal that occurs during fusion welding. In the case of copper-clad steel, diffusion of copper into the weld metal

during fusion causes low ductility and high susceptibility to hot cracking in the weld zone. Fusion welding of 3XXX series alloys clad with 4104 aluminum results in the formation of Mg2Si in the weld zone and the weld is similarly prone to hot cracking and with low ductility. High frequency induction welding of these clad materials allows the cladding metal to be expelled from the bond line when the two strip edges are forged together. The result is a uniform composition and microstructure across the weld heat affected zone.

Induction heating is well suited for post-weld heat treatment because of how rapidly is able to heat metals and is commonly used in line with induction seam welding to stress relieve or anneal tubing after welding. Induction heating is also used for stress relieving or annealing of fusion welded parts.

References

- S. Larrabee, A. Bernhard, Design and Fabrication of

Inductors for Heat Treating, Brazing, and Soldering, in ASM Handbook, Vol. 4C; Induction Heating and Heat Treatment, ASM Intl., 2014, p. 619-632.