Induction Carbide Brazing

May 24th, 2022

Successful Carbide Brazing with Induction

Brazing is a successful and reliable way of joining carbides to steel. Tungsten Carbides (WC) are used in many applications including cutting tools, punches, dies, and numerous other applications. Carbides provide superior wear resistance and extend the life of these various wear and cutting tools.

In this article, we will look at:

What are the factors that play a role in successfully brazing carbides?

What are some of the typical braze alloys used to braze carbides?

Tungsten carbide (WC), also referred to as cemented carbide, is a composite material manufactured by a process called powder metallurgy. Tungsten carbide powder is mixed with a binder metal, usually cobalt or nickel, compacted in a die, and then sintered in a furnace. The term “cemented” refers to the tungsten carbide particles being captured in the metallic binder material and “cemented” together, forming a metallurgical bond between the tungsten carbide particles and the binder (WC – Co), in the sintering process. The cemented carbide industry commonly refers to this material as simply “carbide”, although the terms tungsten carbide and cemented carbide are used interchangeably. Carbide exhibits high compressive strength, resists deflection, and retains its hardness values at high temperatures, a physical property especially useful in metal-cutting applications. It provides long life in applications where other materials would not last or would fail prematurely[I].

Considerations for successfully brazing tungsten carbide

Two main issues to overcome when brazing cemented carbides include managing the stresses caused by differential expansion and contraction rates of parent materials and wetting of the carbide by the braze alloy.

During heating and cooling, the base parent metal will typically expand and contract at a higher rate than the carbide. Tungsten carbide has a thermal expansion rate of approximately 1/3 to 1/2 that of steel. When the brazed assembly cools, residual stress may build within the carbide. Slow uniform cooling of the carbide is always recommended to avoid stressing and possible cracking. Quenching is not recommended as it can cause cracks in the carbides due to the rapid contraction of the parent base metal.

Braze alloy selection for brazing of carbides

Tungsten carbide is difficult to wet. Silver braze alloys with small additions of Nickel (Ni) are typically used to braze carbides to steel. Of course, both the carbide and steel must be clean so the molten braze alloy can wet the mating surfaces completely. Many users will grind the carbide surface to create a clean surface for brazing. Grinding also has the advantage of flattening the surface topography of the carbide which can aid with braze alloy wetting and adhesion. Steel components, similarly, would need to be degreased and cleaned to remove any residual grease, oil, dirt, or other surface contaminants. For more on brazing best practices please read this article, “The Steps for Brazing Success.”

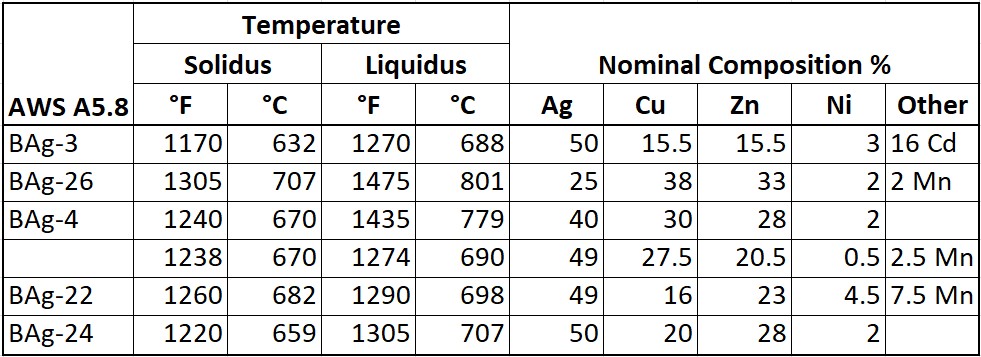

Commercially available silver braze alloys with small additions of nickel (Ni) and Manganese (Mn) will readily wet cemented carbide surfaces. These braze alloys typically exhibit good wetting of tungsten carbides. It is recommended to select a brazing filler metal with the lowest possible brazing temperature to diminish the residual stresses within the joint. Table 1 highlights common silver brazing alloys used to braze carbides to steel. Consult with your braze alloy manufacturer for assistance with selecting a braze alloy.

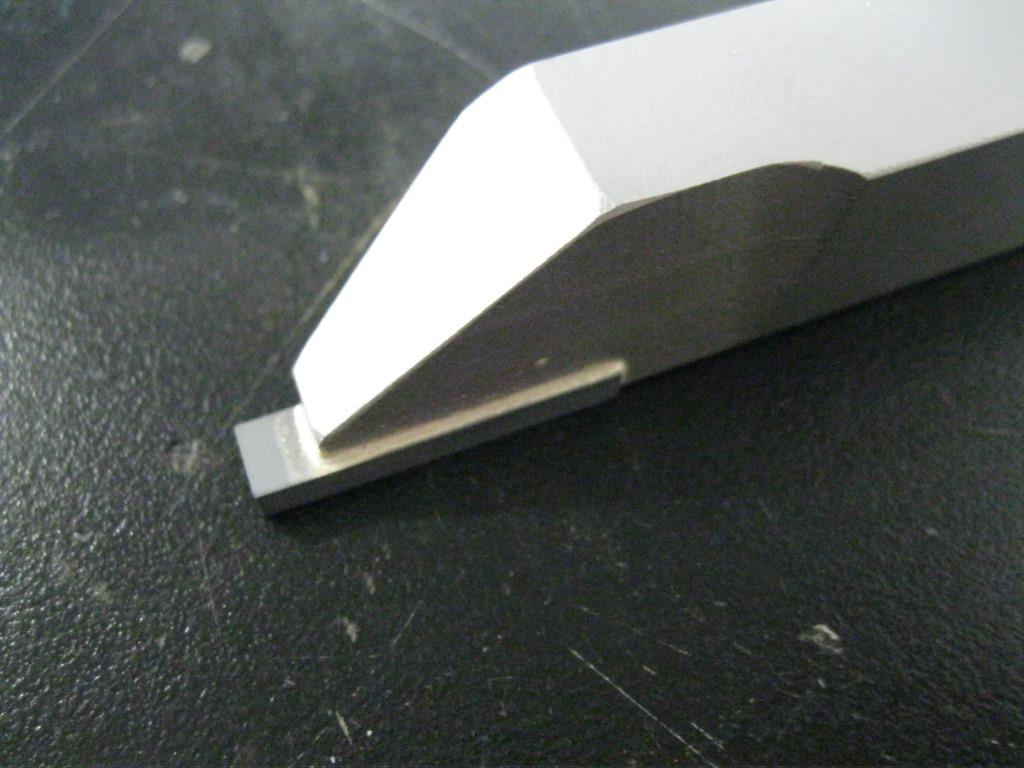

For applications involving the brazing of large carbides, a sandwich braze alloy is often used. If small carbides (1/2 inch2) cannot be utilized, a sandwich alloy is beneficial in preventing cracking and warpage of the carbide. These trimetals are clad with a braze filler bonded to both sides of a copper core. These alloys are sold under tradenames such as Trimet®, trimetal, tri-foil, plymetal, and triply alloys.

Although much of the discussion has been around brazing of tungsten carbide (WC), we would be amiss if we didn’t mention polycrystalline diamond or PCD. The brazing temperature for PCD is generally kept below 1382F (750C) to avoid degradation of the diamond. Often manufacturers of PCD tips to steel bodies will use a low temperature, high silver braze filler metal such as a BAg-24 braze alloy. Some manufacturers use a braze alloy without nickel or manganese, such as BAg-5, or BAg-7 braze alloy with lower melt temperatures and less wetting properties of the carbide and steel.

A brazing flux is used to prevent the oxidation of the surfaces to be joined during the heating of the assembly. Both “white” and “black” flux is used with the common silver braze alloys. Black flux is typically recommended by braze and flux manufacturers as it has the addition of boron and is more effective at higher temperatures.

Induction brazing is a very adaptable process for joining carbide tips, particularly within a production environment. Induction brazing has many advantages over other common heating methods. Reasons to consider using induction heat include:

- Quick, rapid heating

- Controlled, precise heat control

- Selective (localized) heat

- Production line adaptability and integration

- Improved fixture life and simplicity

- Repeatable, reliable brazed joints

- Improved safety

Radyne can design and build inductors (coils) as sizes and shapes change to efficiently heat parts. The inductor shape and the gap between the inductor and part control how the electromagnetic field couples with the part. The correct shape and size of the inductor coil are of critical importance to effectively and efficiently braze carbide to steel.

The typical steps to induction braze carbide are as follows:

- The appropriate flux is applied to properly cleaned steel surfaces

- The braze filler metal, typically a metal shim, is placed into position

- Placement of the carbide tip into location and optionally fluxing and coating the carbide with flux

- Insert the assembly within the induction coil

- Heat and braze the assembly

- Allow the braze alloy to solidify.

- Slowly cool the carbide to minimize cracking of the carbide

Some manufacturers will hold the carbide in place with a non-conductive rod to ensure the carbide remains in contact with steel. It is important that the area to be brazed is heated uniformly. Some techniques operators use include heating the steel at a temperature below the melt point of the braze alloy by adjusting the power level, allowing the steel and carbide to heat uniformly.

Radyne power supplies have the capability to store a part recipe. Once a part profile is created, Radyne induction systems can store a “recipe” profile so that the same power and time are uniform each and every time a component is brazed. A recipe can be generally thought of as a multi-step induction heating process. Most induction heating outcomes require very specific power ramp-ups, time-specific power saturations, intermittent cool downs, etc. In order to provide for all the versatility of your induction heating application, the VersaPower® Xtreme™ induction power supply is designed to allow for precise timing and power outputs. These “recipes” can be password protected once a brazing profile is established.

Optionally, an induction brazing system can be configured with a thermal control package. The Thermal Control Package allows Radyne power supplies to directly interface with a pyrometer to collect temperature data. The power supply can then use this data in real-time to adjust its power output and achieve a desired temperature and heat time specified by the operator or pre-programmed recipe.

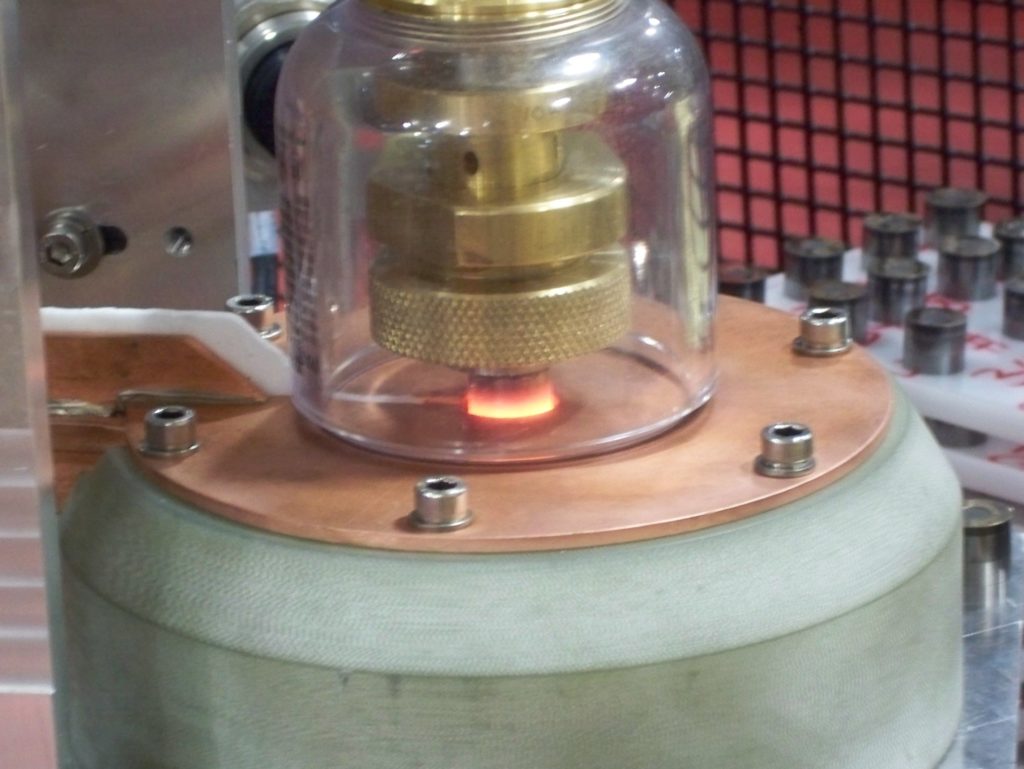

The induction brazing system discussed thus far have been systems for brazing carbides in open air. Radyne can also provide systems to braze carbides in a controlled atmosphere. A controlled atmosphere brazing system utilizes an inert gas, such as nitrogen or argon, reducing the amount of flux needed and potentially eliminating the need to flux components. The inert gas is introduced into an enclosed chamber and a continuous flow of gas displaces the oxygen and minimizes oxidation of the parts.

Conclusion

Brazing of carbides differs from the brazing of similar and dissimilar metals. By paying close attention to good braze principles, coefficient of thermal expansion, proper braze alloy selection, and heating properly, strong, repeatable braze joints can be achieved with induction. Not all brazing applications are strong candidates for induction heating. In situations of low volume, high mix, or irregular shapes where fixturing or the coil design would be extremely complex, furnace brazing or torch brazing with experienced operators may be a more economical choice. However, Induction brazing allows for fast, controllable, precise, energy-efficient, repeatable braze joints for companies that embrace lean manufacturing.

As an induction heating industry leader, Radyne can help you navigate the challenges and realize the advantages of induction brazing. For more information on solutions for induction heating and related processes, please contact us.

This synopsis of carbide brazing alloys is intended to provide an overview of common practices prevalent within the industry today. It is not intended to be a recommendation as each application is unique and the ultimate responsibility lies with each manufacturer to determine the process and fitness for their products.

[i] The Designer’s Guide to Tungsten Carbide [Review of The Designer’s Guide to Tungsten Carbide]. https://Generalcarbide.com/; General Carbide Corp. https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-Designers_Guide_TungstenCarbide.pdf

Trimet® is a registered trademark of Lucas-Milhaupt, Inc.