Custom Applications

Radyne’s expertise in induction can be applied to custom applications, ranging from billet heating to susceptor heating and more. Radyne’s permanently staffed Induction Process Engineering Center (IPEC) performs the necessary process feasibility tests on customer applications. As your one stop shop for induction equipment, you can count on Radyne’s experience.

Click to contact Radyne about custom applications

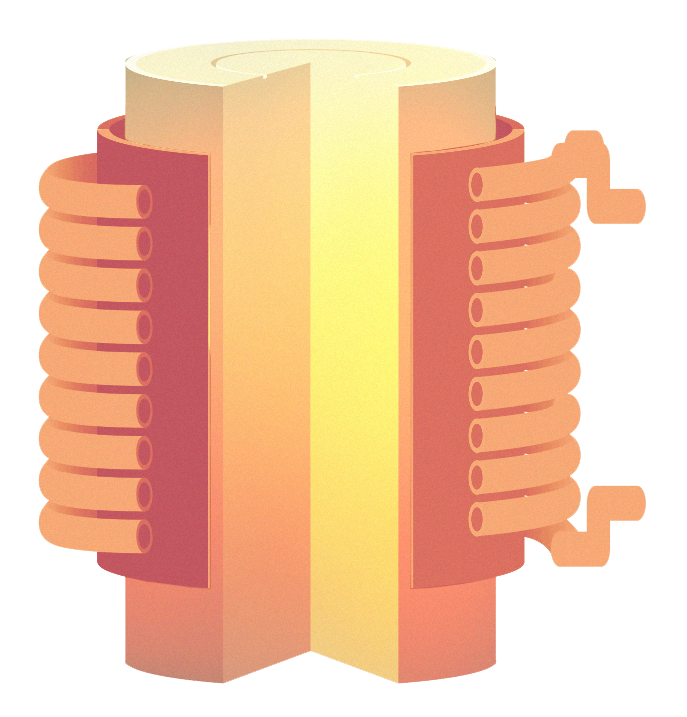

Billet Heating

Induction heating offers many advantages over alternative forms of heating for aluminium and light alloy billets prior to extrusion, rolling, or other forging operations.

Chemical Vapor Deposition

Radyne supplies chemical vapor coating systems of non-metallic and metallic parts, applied in an evacuated chamber containing the parts to be coated and the chemical vapor source.

Coating

Radyne supports coatings for corrosion protection, electrical characteristics, thermal properties, appearance, and other special properties.

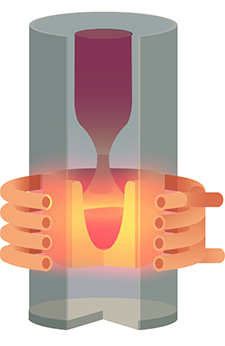

Crystal Growing

Induction heating provides the very accurate temperature control required for successful crystal growth.

Fiber Optics

Radyne has a variety of systems including power supplies and other equipment for Fiber Optics manufacturing.

Induction Melting

Custom-designed induction equipment for high speed and efficient melting of materials.

Susceptor Heating

Susceptors make induction heating applicable for heating all non-metallic and metallic materials, allowing induction heating to become an important tool in the electronics, glass, plastics, and rubber industries.